MPM Gen IV ICCP Systems

MPM’s Generation IV Impressed Current Cathodic Protection (ICCP) Systems provide subsea corrosion protection that is proven to be reliable, durable, and cost effective and are designed for long term operation. The MPM sleds, which house mixed metal oxide (MMO) anodes, have been utilized for corrosion protection of platform jackets and subsea pipelines in water depths up to 1,280 feet (390 meters). Design enhancements incorporated in the Generation IV system now provide an output of up to 1,000 amps. The Gen IV ICCP anode sleds have been installed utilizing remotely operated vehicles (ROVs) and/or divers, and each MPM ICCP system is tailored to the facility requirements and design life.

Why Gen IV ICCP Systems?

Proven Reliability

- Design life up to 40 years

- More than 50 Gen IV systems installed and currently in service, some in areas with current velocity up to 6-knots

- Previous generations in operation since 1996

- Alarms and continuous monitoring available to identify rectifier failure or unintentional shut down

Designed for Durability

- Anode and connection are protected within the structure, not exposed in the water column

- Low-profile design is not vulnerable to trawling, mooring, ROVs, or construction

- All materials and components are the highest quality, thoroughly tested, and designed and manufactured specifically by, or for, MPM

Proven Electrical Connection

- No moving parts, and nothing to fail due to fatigue

- Single electrical connection, tested to 850-psi/1,900 FSW (581m)

- No oil filled junction box, which are prone to leakage

Cost Effective

- Requires no subsea maintenance

- Costs up to half that of traditional CP retrofits

Specifications

High Output Model (HO): 350-1,000 Amps per sled

Weight: Shipped = 970 lbs (440 kg), Completed Dry Weight = up to 9,600 lbs (4,354 kg)

Dimensions: 120 in. long x 96 in. wide x 29 in. high (305 cm x 244 cm x 74cm)

Standard Model (STD): 230-800 Amps per sled

Weight: Shipped = 780 lbs (354 kg), Completed Dry Weight = up to 7,900 lbs (3,538 kg)

Dimensions: 96 in. long x 72 in. wide x 29 in. high (244 cm x 183 cm x 74 cm)

Gen IV System Components

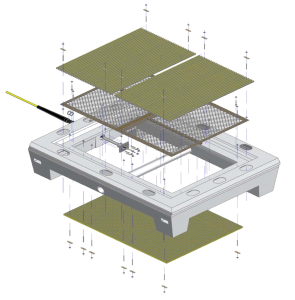

Anode Sleds

The MPM Gen IV anode sled is specifically designed to be low profile and trawl friendly, and incorporates ROV compatible installation and recovery rigging features. Each sled is constructed of molded fiberglass, which houses a mixed metal oxide (MMO) mesh anode. Durable grating is included above and below the anode, which protects it from damage during installation, dropped/lost article impact and ROV contact. The fiberglass components are non-corrosive and chlorine compatible, eliminating risks of deterioration.

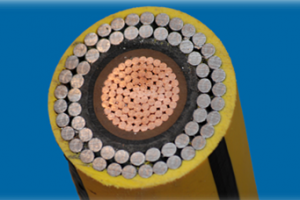

Subsea Power Cables and Cable Connections

MPM’s Standard and HO sled power cables are either single armored or contra-helically wound double armored, both with an HDPE outer jacket. The cables are available various sizes from 2/0 AWG to 1,100 kcmil. MPM’s proven power cable electrical connection is terminated using a single connection directly to the anode. The connections are hydrotested to 850 psi, and torque/tension tested to a minimum of 3X SWL.

Rectifiers

MPM provides oil immersed rectifiers/transformers, supplying up to 1000 amps to the anode sleds. Rectifier cases are 316L SS, supplied with appurtenances to allow SCADA interface to voltage/amperage input/output. All rectifiers are custom built according to the project specifications.

Power Cable Conduits (I-Tubes)

MPM’s multi-conduit power cable I-tube and I-tube clamp designs are based on US West Coast or GOM environmental forces.